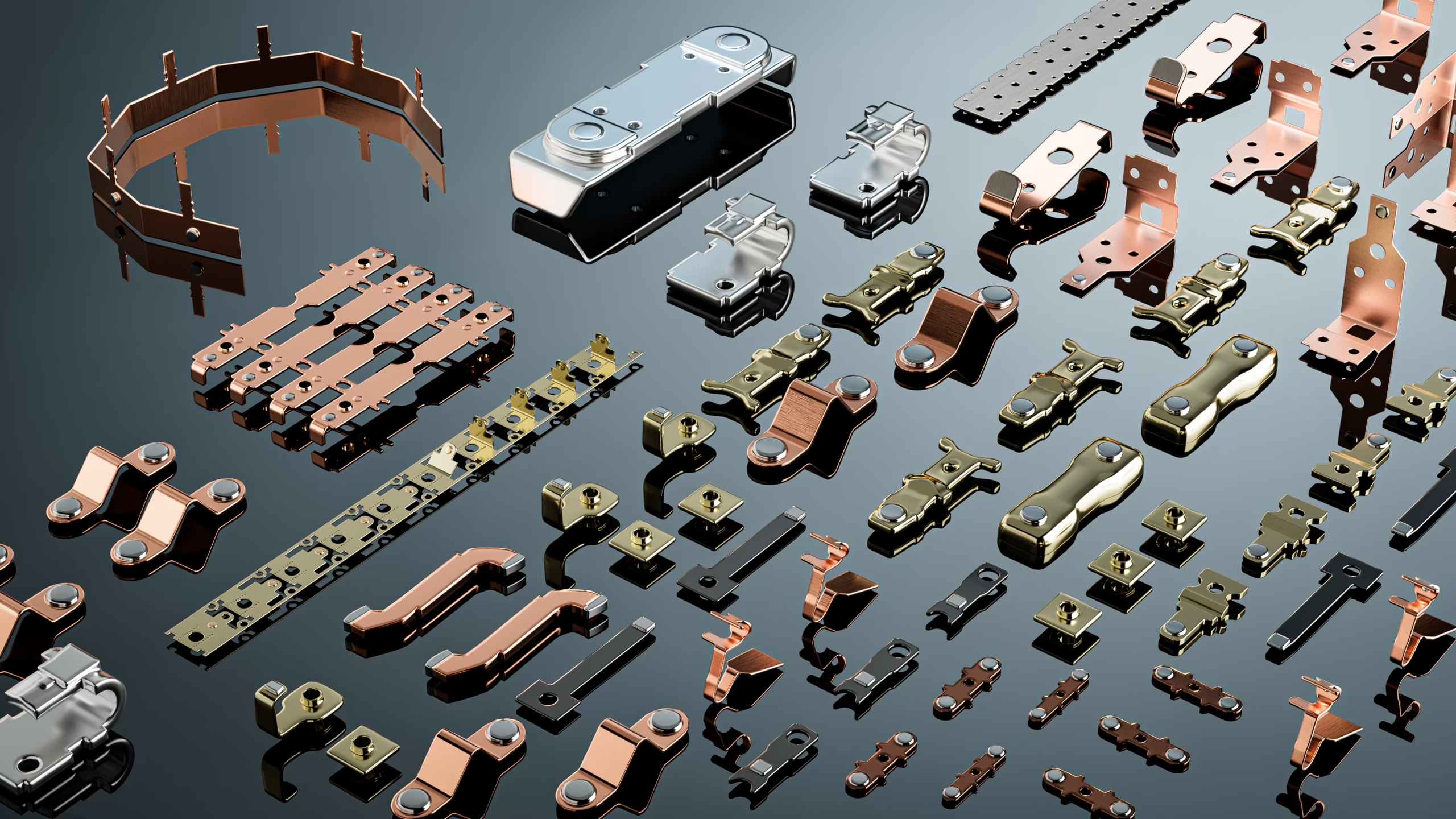

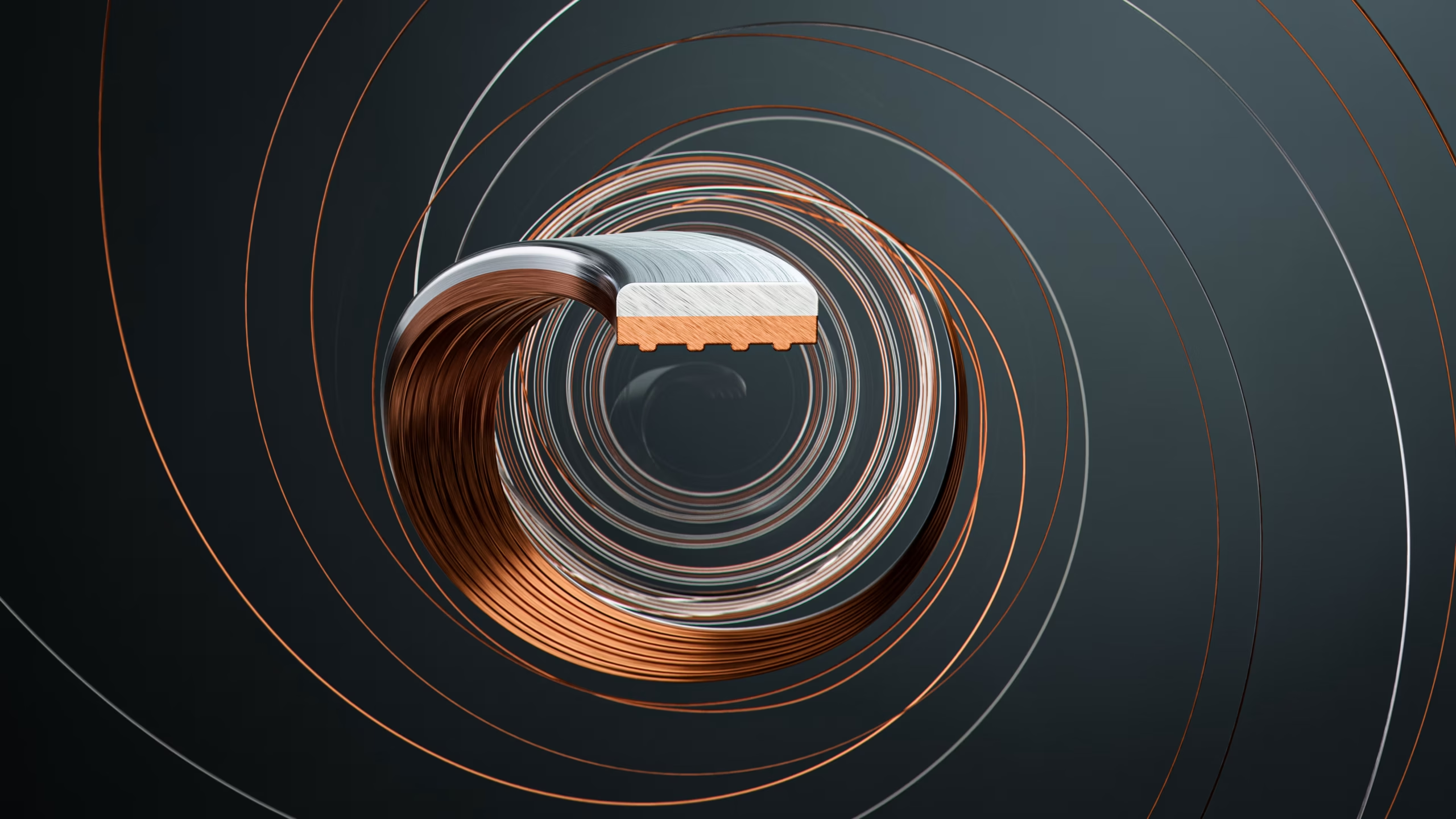

Contact assemblies

Contact assemblies combine contact materials and carrier components to ensure reliable switching functions, reduce assembly effort, and deliver consistent, reproducible quality in demanding industrial series applications.

Available Configurations

- Assemblies consisting of contact tips, carriers, and connecting elements

- Supplied as individual parts, on strip, or as ready-to-install assemblies

- Custom geometries according to drawings and process requirements

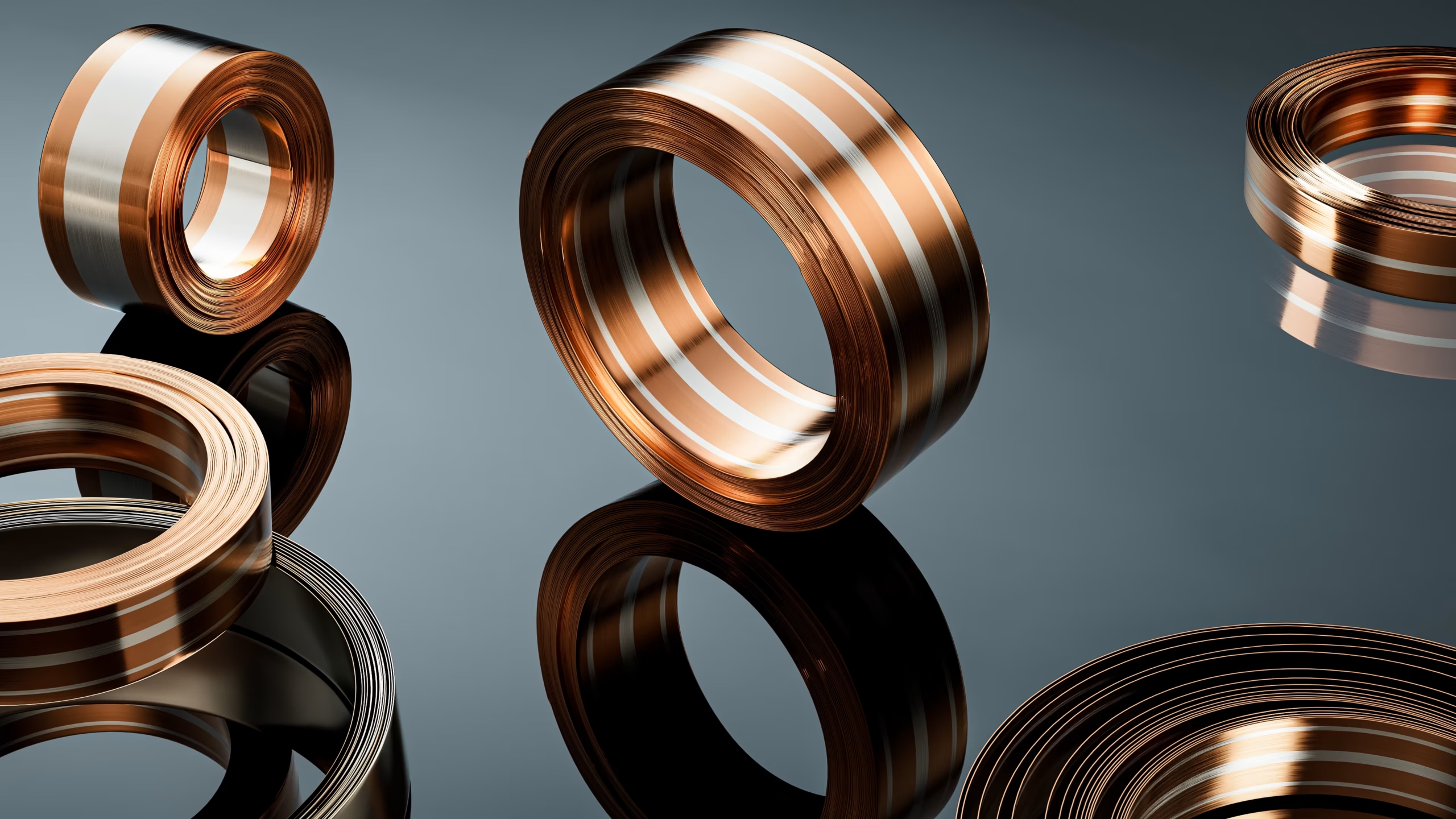

Materials

- Silver-based contact materials (e.g. AgNi, AgSnO₂, AgZnO, AgCu)

- Carrier materials made of copper and copper alloys

- Material combinations tailored to switching load and application

Applications

Application areas of our contact parts in electrical engineering

Relays

Miniature switches

Contactor

Circuit breaker

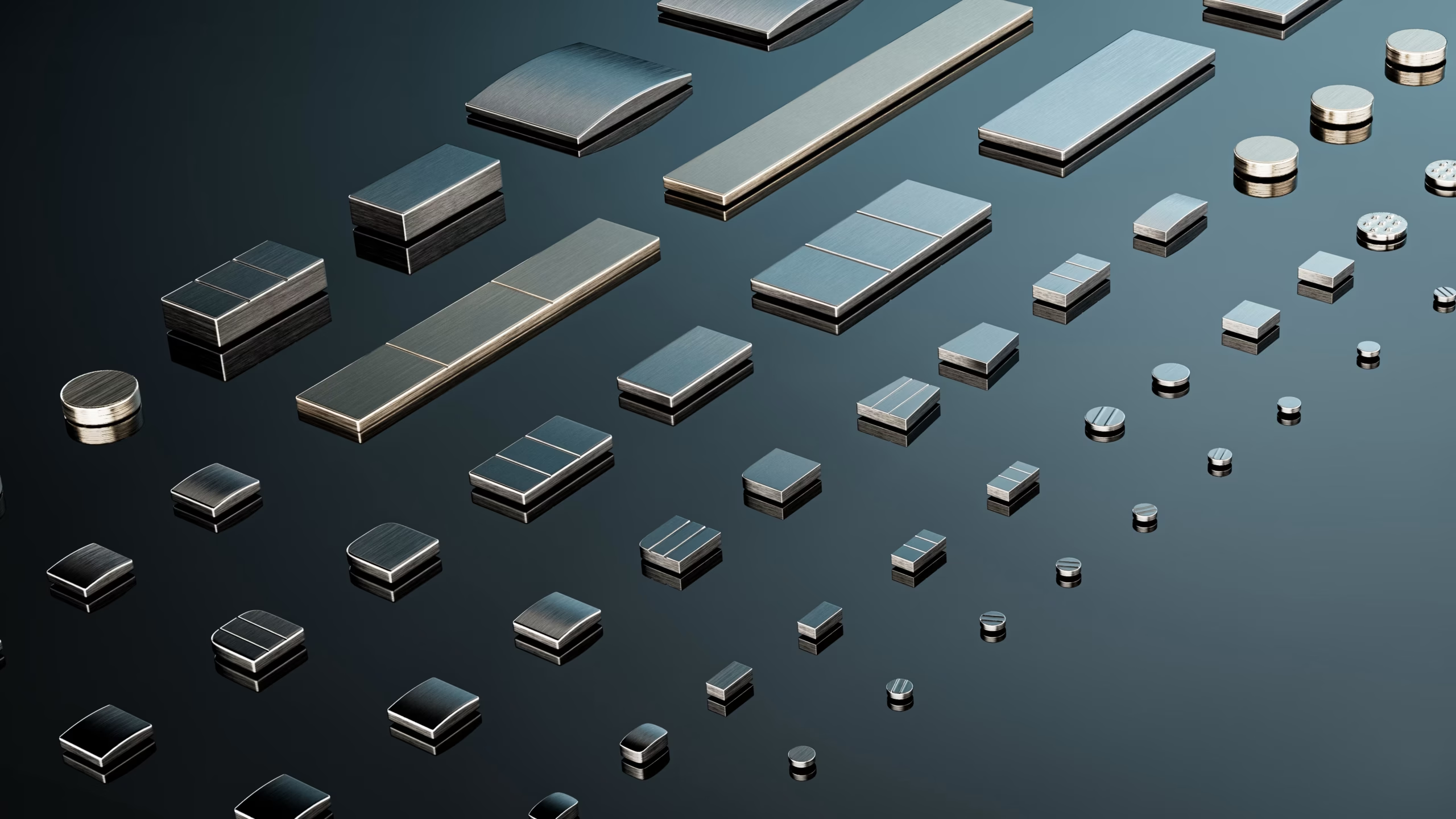

Contact profiles

Precision-manufactured contact profiles for a wide range of switching applications

Blog

Knowledge

Expertise in material selection, manufacturing, and application

Contact rivets in electrical engineering

Contact rivets are widely used contact parts in low-voltage switching devices. This reference article covers design and geometry, common silver-based materials, manufacturing and setting processes, typical applications, and practical selection criteria for engineering and purchasing.

Manufacturing of electrical contacts for industrial use

Manufacturing of electrical contacts: materials, forming and joining processes, series stability, quality assurance, and typical failure modes.

Contact materials and alloys for electrical contacts

The right choice of contact materials determines conductivity, contact lifetime, and switching performance. Learn more about materials and alloys.